\[ \]

\[ \]

\[ \]

Issue No 51, 20 November 2023

By: Anthony O. Ives

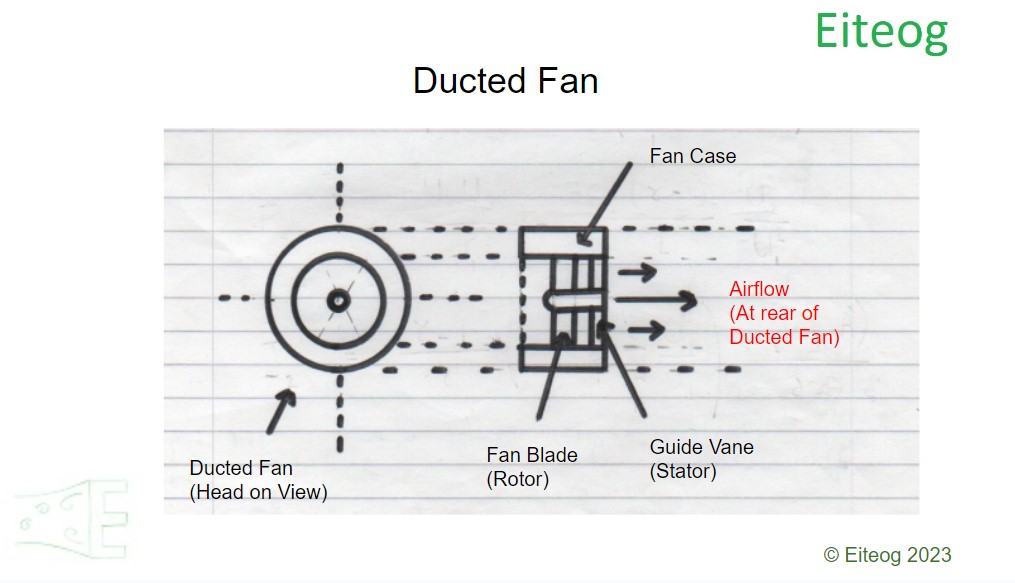

A ducted fan could be simply described as propeller inside a duct. Ducted fans give a number of performance benefits the most obvious being they reduce tip vortices at the fan blade tips [1]. However, there are other advantages such as you can design the duct to give the flow characteristics you want upstream or downstream this means you may not need varible pitch blades. You can also use varible pitch guide vanes which are more or less stators [2] instead of variable pitch fan blades which are more complex as they rotate and guide vanes do not.

Other advantages also that they are safer as the spinning fan is inside a casing so people are less likely to inadvertently walk in to it. The main disadvantages are that they add more weight as you will now have the weight of the casing and accessories. There can also be aerodynamic performance issues such as can flow separation at the duct walls if the ducted fan inlet is at an extreme angle to the flow. The picture below gives a simple schematic of ducted fan:

Ducted fans are more commonly used in turbofan engines [2] where they increase efficiency and reduce noise particularly for commerical transport aircraft. Turbojet engines generally had a smaller blade radius which results in lower tip velocities [3] which then gives a lower compressor pressure ratio. Turbine engines are more efficient when they have higher pressure ratios. There is a general limitation on how much you can increase the blade radius of turbojet as all the flow passing through a turbojet must be heated in the combustor. However, with a turbofan not all the flow passes through the combustor [2] so therefore you can make the blade radius larger the main limitation is ground clearance. Ultra high bypass ratio turbofans are being researched as way of further increasing efficieny so there does not seem to be limitation how large you can make the fan apart from practical issues of fitting such a large engine on an aircraft.

Turboprops are actually slightly more efficient than turbofans but a ducted fan is needed in high speed aircraft due to the need to reduce flow before it comes in contact with fan. Propellers also produce a lot of noise at high speed due to the blade tip velocities approaching the speed of sound producing shock waves at the tips. Fan blades in a ducted fan also experence the same problems however, a ducted fan allows the installation at the duct walls of noise absorbing acoustic liners.

Vertical Take off and Landing (VTOL) using ducted fan was investigated by NASA using the Bell X-22 [4], out all the VTOL experimental aircraft that NASA experimented with this seemed to be the one that was most successful. However, the concept of using ducted fan for VTOL has never been used but the recent surge in eVTOL (electric powered VTOL), some designs are using ducted fans. The Lockheed Martin F-35B Lighting II [4] uses a dedicated ducted fan for vertical flight.

Helicopters obviously never make use of ducted fans for their main rotor but some tailrotor designs known as Fenestron tail rotor [5] are a form of ducted fan. A fenestron has many advantages, that is increased performance and safety. It can also prevent accidents on the ground with people contacting tail rotor which can happen unfortunately, so a fenestron tail rotor prevents this.

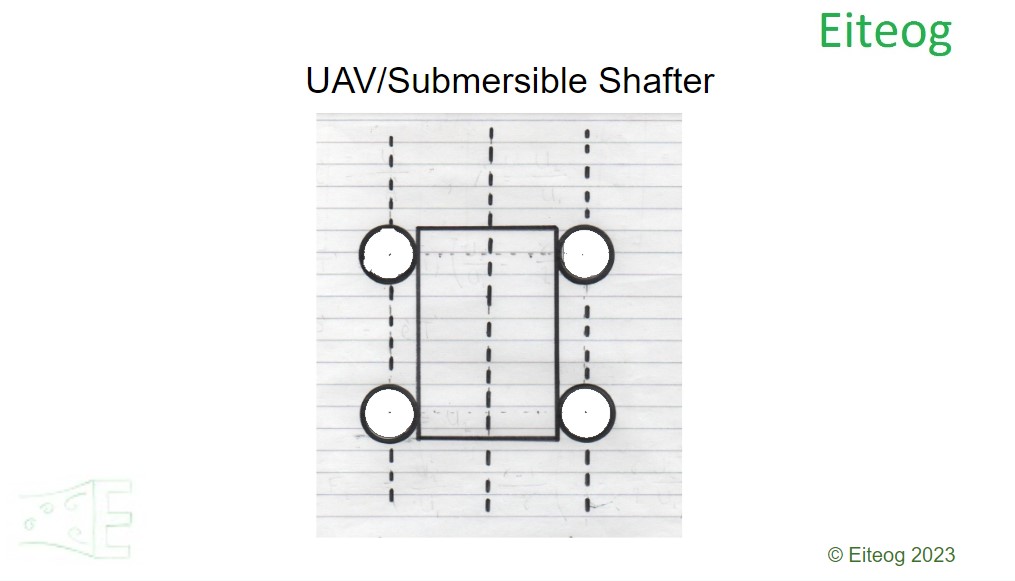

As a engineering student I came up with the idea of 'Shafter' a quadcopter type UAV (Unmanned Air Vehicle) which could also operate underwater obviously I thought this was a great idea. There is probably not many really practical purposes for a Submersible UAV as it can only really be optimised for either flight or underwater. My plan was I could use to go down shafts (hence the name 'Shafter') that had regions of air and regions of liquid, usually the upper section of the shaft would be air and the bottom section would be liquid. I was thinking maybe the construction or oil and gas industry had some need for it. The other purpose that it could be used for is specialised cave rescues where there are cavities filled with water and some open areas. I might do some future article looking at 'Shafter' just as novelity. I decided to use ducted fans on Shafter for some reason, I was maybe thinking the fan case would protect the fans in case it contacted the walls of shaft. The picture below shows the 'Shafter' design which is quite basic./p>

Please leave a comment on my facebook page or via email and let me know if you found this blog article useful and if you would like to see more on this topic. Most of my blog articles are on:

Mathematics

Helicopters

Woodworking and Boatbuilding

If there is one or more of these topics that you are specifically interested in please also let me know in your comments this will help me to write blog articles that are more helpful.

References:

[1] http://www.eiteog.com/EiteogBLOG/No35EiteogBlogDrag.html

[2] http://www.eiteog.com/EiteogBLOG/No49EiteogBlogGasTurbine.html

[3] http://www.eiteog.com/EiteogBLOG/No10EiteogBlogCircle.html

[4] The X-Planes X-1 to X-45, Jay Miller, 2nd Edition, 2001, Midland Publishing

[5] Principles of Helicopter Flight, 2nd Edition, W. J. Wagtendonk, 2006, Aviation Supplies & Academics

Disclaimer: Eiteog makes every effort to provide information which is as accurate as possible. Eiteog will not be responsible for any liability, loss or risk incurred as a result of the use and application of information on its website or in its products. None of the information on Eiteog's website or in its products supersedes any information contained in documents or procedures issued by relevant aviation authorities, manufacturers, flight schools or the operators of aircraft, UAVs.

For any inquires contact: [email protected] copyright © Eiteog 2023