\[ \]

\[ \]

\[ \]

Issue No 49, 23 October

By: Anthony O. Ives

Most commerical helicopters are powered by gas turbine engines because they have a higher thrust to weight ratio than piston engines. As piston engines become more powerful their increase in weight makes them impractical for aviation whereas gas turbine engines can produce a larger amount of power for less weight. However, the disadvantages of gas turbines is they have higher fuel consumption and they are more expensive to manufacture this is why piston engines are still used in light aircraft and helicopters.

Small gas turbines are also less efficient than larger gas turbines, this is the result of the blade tip velocities [1] being lower. Blade tip velocites can be calculated in similar way to propeller and helicopter rotor blade tip velocities. The small gas turbine due to their size will have smaller radius blades, hence their compression ratio will be lower.

Gas turbines work by sucking air in from the atmosphere compressing to as high a pressure it can achieve, then heating it in the combustion chamber to as high a temperature as practically possible. The heated, compressed air passes through a turbine section which extracts some energy from the air to turn the compressor blades through a shaft which connects the turbine rotors to the compressor rotors. The turbines and compressors both consist of rotors and stators, both could be considered to be wing type structure with an airfoil cross-section similar to wings. The rotor is the rotating component whereas the stator is a fixed component. The turbine and combustion chamber are the most expensive components of the gas turbine because they require expensive materials and involve expensive manufacturing techniques that are required to withstand the extreme temperatures and provides means for cooling. The efficiency of a gas turbine is really limited by the highest temperature that can be achieved and is possible in the combustion chamber.

The gas turbine was intially developed in Germany [2] during the second world war and also independently in Britain [3] at the same time. Early versions of the gas turbines where mainly turbojets, British designs intially used centrifugal compressors whereas German designs concentrated on axial compressors. In some other articles I will discuss compressors, turbines in more detail, but an axial compressor is like a propeller air is drawn through it whereas a centrifugal draws air into its center and then throws it out radially to compress it. If you do not understand this explanation completely watch out for a later article I will do on compressors. Turbines also can exist in two forms which operate in a similar reverse way only they are called radial and axial turbines. In modern large gas turbines axial compressors and turbines dominate however, smaller gas turbines like those used in helicopters do contain centrifugal compressors.

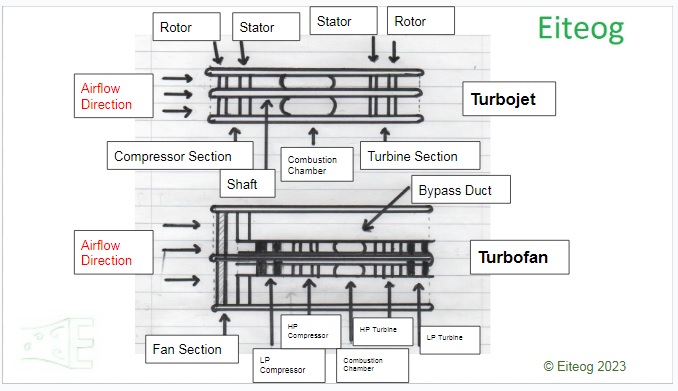

Turbojet gas turbines are the early basic form of a gas turbine where all the flow sucked in the inlet passes through the compressor, then into the combustion chamber, out into the turbine and finally produce the jet of hot air which produces the thrust to propel the aircraft. Turbojets are no longer used on modern aircraft they have been replaced by turbofan gas turbines which are essentially a ducted fan with a turbojet core where the ducted fan produces most of the thrust which is overall more efficient, the core of the turbofan which is essentially a turbojet really produces the power to turn the fan. In another article I will discuss ducted fans and their relevance to helicopters and other VTOL aircraft. The airflow passing throught the core section is referred to as core flow, whereas the flow that passes through the ducted fan is referred to as the bypass flow. See the picture below for a very simple illustration of the turbojet and turbofan engines.

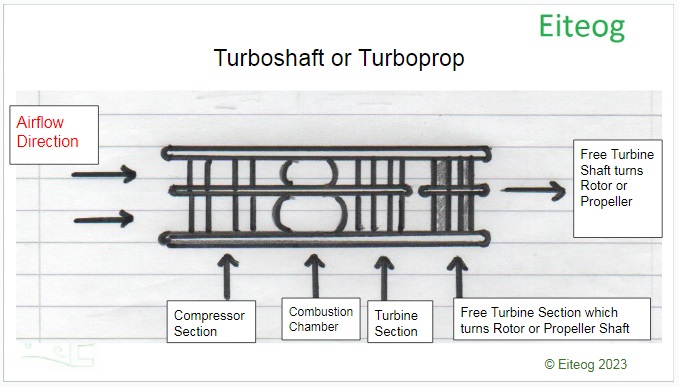

Another variation of a gas turbine used in aviation is the turboprop or turboshaft depending on whether it is used in a fixed wing aircraft to turn a propeller or a helicopter to turn a rotor. As we are more interested in helicopters I am going to refer to it as a turboshaft engine. A turboshaft is essentially a small turbojet engine but rather than using the hot air coming out of the exhaust to produce forward thrust it is used to turn another turbine referred to as a free turbine. The free turbine is attached a shaft which is attached to a propeller in the case of a turboprop engine or rotor in the case of turboshaft engine. A very simple diagram of a turboprop/turboshaft engine is given below.

Turboshaft/turboprop engines are the one type of gas turbine engine that use centrifugal compressors because centrifugal compressors generally produce higher compression ratios for lower intake mass flows. However, turboshaft engines such as the Allison 250 (now known as Roll Royce 250) uses a combination of both axial and centrifugal compressors. Smaller turboshaft engines such as the Rolls Royce 300 use only centrifugal compressors. I am going to write some further articles on gas turbine engines mainly concentrating on turboshaft engines they will go into more detail on the mathematical equations and principles [4] of gas turbine engines and their components.

Please leave a comment on my facebook page or via email and let me know if you found this blog article useful and if you would like to see more on this topic. Most of my blog articles are on:

Mathematics

Helicopters

Woodworking and Boatbuilding

If there is one or more of these topics that you are specifically interested in please also let me know in your comments this will help me to write blog articles that are more helpful.

References:

[1] http://www.eiteog.com/EiteogBLOG/No10EiteogBlogCircle.html

[2] German Jet Engine And Gas Turbine Development, 1930-1945, Antony L. Kay, 2002, Airlift Publishing Ltd

[3] The Development of Jet and Turbine Aero Engines, 3rd Edition, Bill Gunston, 2006, Patrick Stephens Ltd

[4] Gas Turbine Theory, Herb Saravanamuttoo, Gordon Rogers, Henry Cohen, 2001, Prentice Hall

Disclaimer: Eiteog makes every effort to provide information which is as accurate as possible. Eiteog will not be responsible for any liability, loss or risk incurred as a result of the use and application of information on its website or in its products. None of the information on Eiteog's website or in its products supersedes any information contained in documents or procedures issued by relevant aviation authorities, manufacturers, flight schools or the operators of aircraft, UAVs.

For any inquires contact: [email protected] copyright © Eiteog 2023